OML offer a large range of innovative clamping equipment and is known for its line of 5-axis and production vices. They have evolved their workholding devices to meet today’s competitive standards for 5-axis accuracy, speed and ease of use, and the company’s workholding systems are some of the most repeatable and rigid available.

OML Genius High Precision Vice for 5 axis machine tools

OML Genius High Precision Vice for 5 axis machine tools

GENIUS is the first vice designed for the 5 axis-machine tools which can also be used for high precision milling operations. Read More… OML Modular Workholding Systems

OML Modular Workholding Systems

The modular system allows the user to realise the maximum number of workholding combinations with the minimum investment in equipment. Read More… OML Tombstones

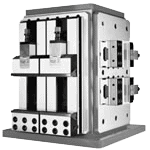

OML Tombstones

The Tombstones are supplied standard with the base machined to the table of the machine tool. Read More… OML IMG Self Centering Vice

OML IMG Self Centering Vice

The IMG self centering vices can be easily transformed into fixed vices or double clamping vices. Read More…

OML APS (Automatic Positioning System)

OML APS (Automatic Positioning System)

This is a universal connection between the machine tool, the clamping device and/or the workpiece. Read More… OML SinterGrip Clamping Inserts

OML SinterGrip Clamping Inserts

OML’s SinterGrip vice jaws make it easy to get a tight grip on as little as 3.5 mm of part material for high-rate, high-accuracy metal removal in a single setup. Read More…