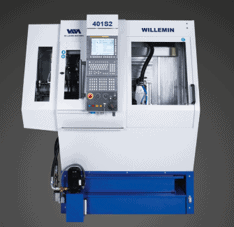

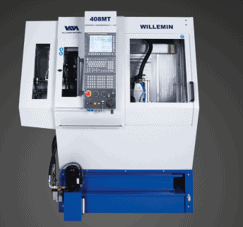

Willemin-Macodel 40 Series

Highly compact, the Willemin-Macodel 40 series benefits from the latest technological developments. With its ingenious design ensuring it offers first rate performances.

Highly compact, the Willemin-Macodel 40 series benefits from the latest technological developments. With its ingenious design ensuring it offers first rate performances.

The range of equipment, such as tool magazine, part inspection, tool measurement, clamping devices or manipulators, provides great flexibility for the production of small or medium runs of parts.

Benefiting from the latest technological developments, the 408B machining centre is perfect for cutting-edge industries. These include watchmaking, jewelery, medical, and mechanical sub-contracting.

The 408MT can be equipped with an automatic back machining unit fitted on a U axis. This unit, which can house either a precision vice or grippers for internal or external clamping, is driven by an indexing movement which enables secondary machining of the cut face.

The 408S2 is an ultra high-precision dual divider capable of handling milling operations with great angular resolution and turning operations on the C axis up to 4000 rpm.