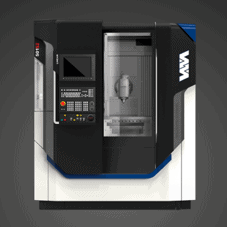

Willemin-Macodel 50 Series

A multi-process machining centre dedicated to machining complex parts.

A multi-process machining centre dedicated to machining complex parts.

The 501S2 is a 3- to 4-axis machining centre designed to machine complex workpieces. Primarily designed for high-precision milling operations, it benefits from “full linear” technology.

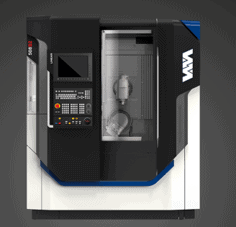

The 508S2 is a machining centre with 5 simultaneous axes designed to machine complex prismatic workpieces. It benefits from “Full Linear” technology, all the linear and rotary axes are equipped with direct drive motors.

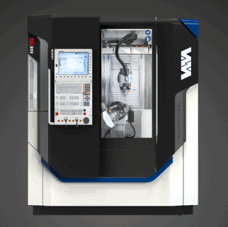

The 508MT2 is a multi-process machining centre dedicated to machining complex parts from bar stock or in one-piece mode.

The 508TB2 machining centre is dedicated to the production of turbine blades from 20 to 120 mm in length.